How do white or light gray concrete floors increase workplace productivity and employee satisfaction?

12.6.2022

Light reflection and improved productivity

In several studies, proper lighting has been a key factor in increasing workplace productivity and employee satisfaction. As environmental aspects and green building solutions (Leeds certificate) have grown in popularity, lighting technology has dramatically improved and industrial warehouses are incorporating these advanced, energy-efficient means of lighting into their operational expenses. However, there is one thing that the lighting engineers do not include in their calculations, and that is reflection.

In the manufacturing sector, a lot of studies have been done about manufacturing efficiency, especially in the field of labor productivity. All the environmental factors have been studied, however one of the things which has been overlooked for years is lighting.

White Concria Optimal Slab™ installation

In several studies proper lightning has been a key factor in increasing workplace productivity and employee satisfaction. As environmental aspects and green building solutions (Leeds certificate) have grown in popularity, the lighting technology has dramatically improved and industrial warehouses are incorporating these advanced, energy-efficient means of lighting into their operating expense. However, there is one thing that the lighting engineers do not include in their calculations; reflection.

Light reflection and improved productivity

In several studies, proper lighting has been a key factor in increasing workplace productivity and employee satisfaction. As environmental aspects and green building solutions (Leeds certificate) have grown in popularity, lighting technology has dramatically improved and industrial warehouses are incorporating these advanced, energy-efficient means of lighting into their operational expenses. However, there is one thing that the lighting engineers do not include in their calculations, and that is reflection.

In the manufacturing sector, a lot of studies have been done about manufacturing efficiency, especially in the field of labor productivity. All the environmental factors have been studied, however one of the things which has been overlooked for years is lighting.

White Concria Optimal Slab™ installation

In several studies proper lightning has been a key factor in increasing workplace productivity and employee satisfaction. As environmental aspects and green building solutions (Leeds certificate) have grown in popularity, the lighting technology has dramatically improved and industrial warehouses are incorporating these advanced, energy-efficient means of lighting into their operating expense. However, there is one thing that the lighting engineers do not include in their calculations; reflection.

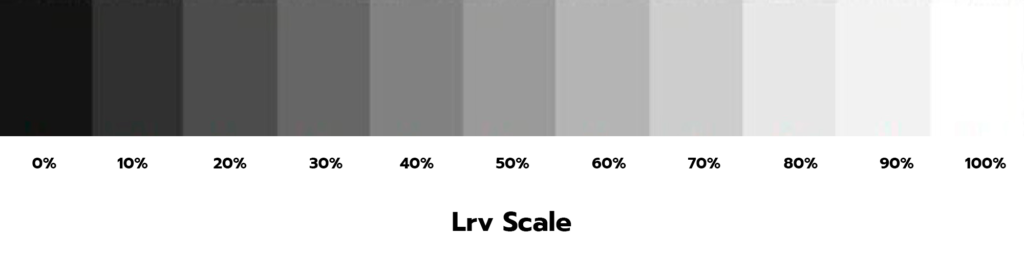

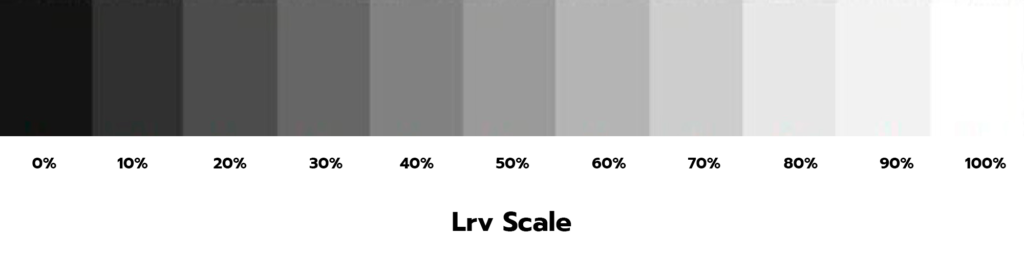

When talking about productivity and energy savings, it is imperative to look at the LRV (Lighting Reflectivity Value) of the floors.

Using the lighting reflectivity scale for polished concrete shows how not only the reflection but the color of the surface is a major part of lighting efficiency in the workplace. To obtain the white concrete floor reflection that is truly needed to increase illumination you need a polished floor with minimum of 75 DOI (Distinctness of Image). This should not be confused with gloss, as it is not the same.

Increasing these surface’s LRV Scale percentage reduces the amount of light needed to achieve the desired illumination for the task at hand

When talking about productivity and energy savings, it is imperative to look at the LRV (Lighting Reflectivity Value) of the floors.

Using the lighting reflectivity scale for polished concrete shows how not only the reflection but the color of the surface is a major part of lighting efficiency in the workplace. To obtain the white concrete floor reflection that is truly needed to increase illumination you need a polished floor with minimum of 75 DOI (Distinctness of Image). This should not be confused with gloss, as it is not the same.

Increasing these surface’s LRV Scale percentage reduces the amount of light needed to achieve the desired illumination for the task at hand

When you increase LRV by 75 %, facilities will see:

- Significant Energy Savings

- Lower amount of human errors

- Better quality control

- Increased employee satisfaction

- Improved safety

These effects are documented in the ANSI, Lighting Standards Document, “Proper illumination is essential for the optimization of safety, comfort and productivity in the workplace; workplace lighting also dictates quality of perception, mood, and performance levels of employees.”

Thanks to patent pending Concria Optimal Slab™ solution, white or light gray color polished concrete floors can be installed faster and more cost-effectively than ever before!

White polished concrete or Epoxy?

Both white polished concrete and epoxy floor coatings are considered good choices for industrial floors and production facilities. Both systems are known to be budget-friendly, efficient, and promise to give a unique look to the floor.

Biggest difference is in lifetime

The lifetime of epoxy depends on the traffic and the volume it must withstand, typically lasting between 3 to 5 years. Concria Optimal Slab floor can last up to 30 years and, most importantly, the cost of refurbishing Optimal Slab will only be a fraction of the epoxy refurbishing cost.

One of the only reasons that makes epoxy a preferred choice for flooring is its ability to not react to heavy chemicals and acids, otherwise Concria Optimal Slab™ will be the first choice.

If you would like more information, please get in touch with our sales team at: [email protected]

Mika Ahonen

CTO and Founder of Concria

READ MORE ABOUT OUR SOLUTIONS

When you increase LRV by 75 %, facilities will see:

- Significant Energy Savings

- Lower amount of human errors

- Better quality control

- Increased employee satisfaction

- Improved safety

These effects are documented in the ANSI, Lighting Standards Document, “Proper illumination is essential for the optimization of safety, comfort and productivity in the workplace; workplace lighting also dictates quality of perception, mood, and performance levels of employees.”

Thanks to patent pending Concria Optimal Slab™ solution, white or light gray color polished concrete floors can be installed faster and more cost-effectively than ever before!

White polished concrete or Epoxy?

Both white polished concrete and epoxy floor coatings are considered good choices for industrial floors and production facilities. Both systems are known to be budget-friendly, efficient, and promise to give a unique look to the floor.

Biggest difference is in lifetime

The lifetime of epoxy depends on the traffic and the volume it must withstand, typically lasting between 3 to 5 years. Concria Optimal Slab™ floor can last up to 10 years and, most importantly, the cost of refurbishing Optimal Slab will only be a fraction of the epoxy refurbishing cost.

One of the only reasons that makes epoxy a preferred choice for flooring is its ability to not react to heavy chemicals and acids, otherwise Concria Optimal Slab™ will be the first choice.

If you would like more information, please get in touch with our sales team at: [email protected]

Mika Ahonen

CTO and Founder of Concria