DECORATIVE CONCRETE REVOLUTION!

We invite you to be part of concrete revolution. Thanks to patent pending Concria Optimal Slab™ Deco topping system polished design concrete floors can be installed faster than ever before! Topping is applied on freshly laid concrete. Normally concrete floor can be polished 28 days after casting. Optimal Slab™ surface can be ground and polished into high gloss in just 7 days after casting as compression strength is already over 5000 psi. With Concria™ Fast power trowel polishing system it’s possible to grind and polish the surface 80 % faster than with traditional grinding methods.

DECORATIVE POLISHED CONCRETE REVOLUTION!

We invite you to be part of concrete revolution. Thanks to patent pending Concria Optimal Slab™ Deco topping system polished design concrete floors can be installed faster than ever before! Topping is applied on freshly laid concrete. Normally concrete floor can be polished 28 days after casting. Optimal Slab™ surface can be ground and polished into high gloss in just 7 days after casting as compression strength is already over 5000 psi. With Concria™ Fast power trowel polishing system it’s possible to grind and polish the surface 80 % faster than with traditional

grinding methods.

Durable, long-lasting and stylish floor

Polished design concrete is not only a practical and economical option, but it’s also a stylish one. Current design trends have seen polished concrete become more and more popular for designers and architects looking for an upscale look. The striking aesthetic of polished concrete keeps buildings looking modern, sleek and clean.

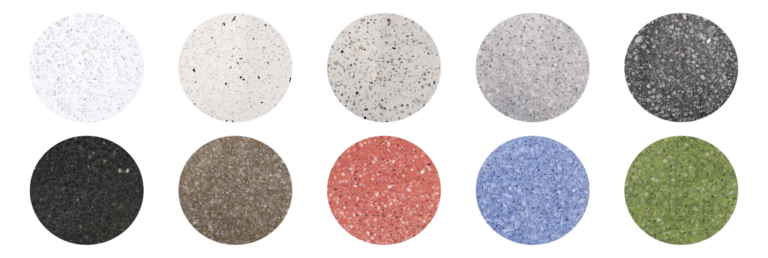

The Concria brand offers a range of standard colors, but specific colors can be created too. The level of gloss can be adjusted based on the desired look of the finished product, with a high-gloss finish providing an attractive shine that looks modern without appearing too industrial or sterile. Concria’s crown jewel is Pure White topping with a high-gloss finish.

Concria OPTIMAL SLAB™ Deco can be applied on

Stores, big-box retailers

Shopping centers, Exhibition centers

Museums, libraries

Schools, universities

Durable, long-lasting and stylish floor

Polished design concrete is not only a practical and economical option, but it’s also a stylish one. Current design trends have seen polished concrete become more and more popular for designers and architects looking for an upscale look. The striking aesthetic of polished concrete keeps buildings looking modern, sleek and clean.

The Concria brand offers a range of standard colors, but specific colors can be created too. The level of gloss can be adjusted based on the desired look of the finished product, with a high-gloss finish providing an attractive shine that looks modern without appearing too industrial or sterile. Concria’s crown jewel is Pure White topping with a high-gloss finish.

Concria OPTIMAL SLAB™ Deco can be applied on

Stores, big-box retailers

Shopping centers, Exhibition centers

Museums, libraries

Schools, universities

ALL IN ONE SOLUTION

Concria Optimal Slab™ Deco system in a nutshell

This unique system makes it possible to get polished colorful concrete or terrazzo topping budget-friendly and super-fast. Revolutionary Optimal Slab™ Deco is an ’All in One’ solution. It includes all systems, chemicals, and products needed to design concrete floor topping and daily maintenance. This unique floor is made for you only by Certified Concria™ Contractors with the assistance of Concria™ Team Professionals.

CONCRIA OPTIMAL SLAB™ DECO SYSTEM INCLUDES

Deco, concrete topping system

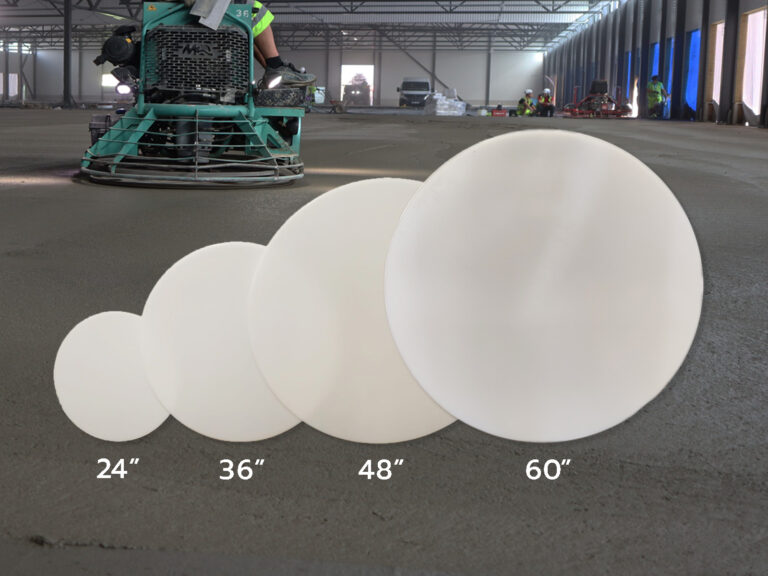

Plastic Floating Pans

Slide Blades, finishing blades

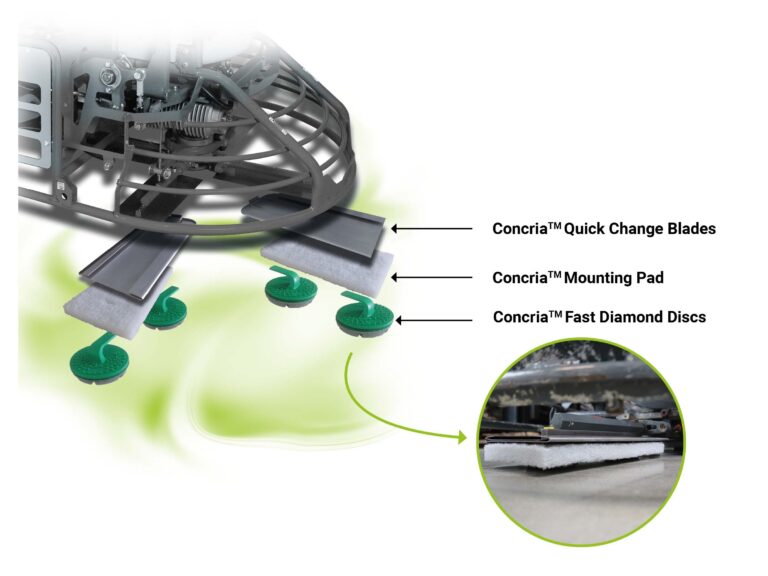

Fast, Power Trowel polishing system

Trowel Hard, finishing aid and hardener

Shield, superhydrophobic sealer

HIGH-QUALITY SURFACE WITH NANO-SIZED TECHNOLOGY

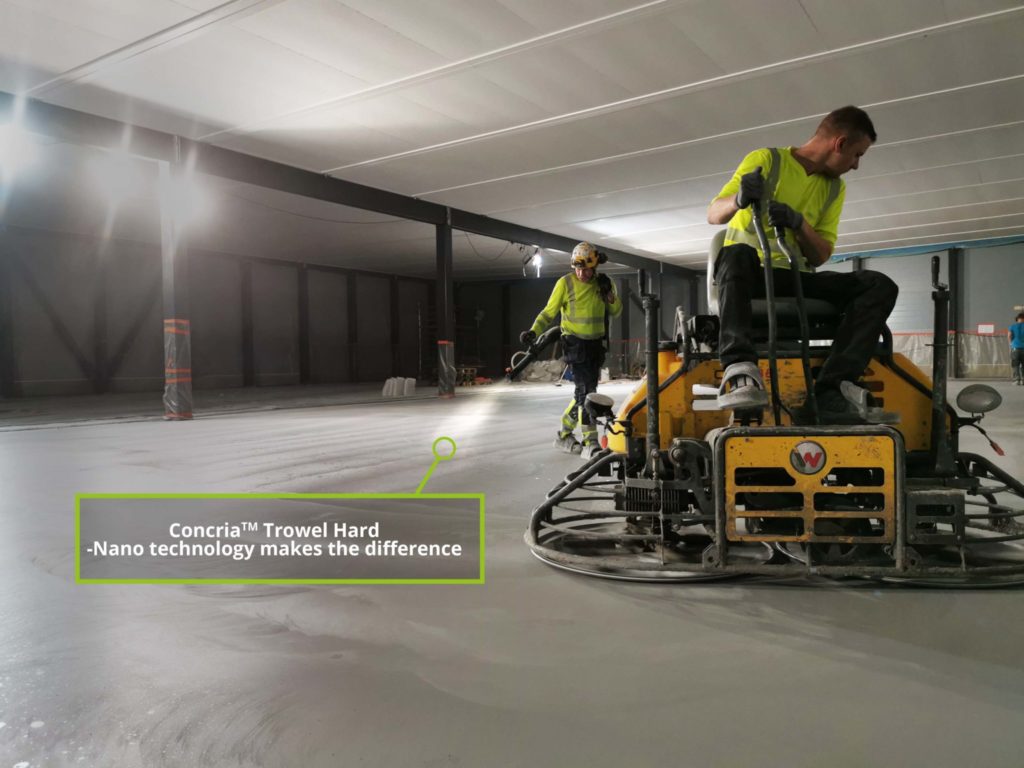

Concria™ Trowel Hard makes topping cement hydration more efficient. Well hydrated, dense cement paste slows moisture loss during finishing and permanently improves the topping performance. Because of nano silica technology, the risk for delamination, curling and cracking and other drying-related pathologies are significantly reduced. Trowel Hard improves the surface consolidation, and the densifying reaction increases the surface compressive strength and durability, creating an extremely abrasion-resistant. Topping is treated with nano silica during the casting and doesn’t need any silicate (Lithium, Sodium, Potassium) treatment later.

Main benefits

Super-fast application

Polishable in 7 days

Minimum risk of efflorescence, delamination, curling and crazing

2 x more durable than 5000 psi polished concrete

3 x more durable than terrazzo tiles

Green solution (Low VOC)

ALL IN ONE SOLUTION

Concria Optimal Slab™ Deco system in a nutshell

This unique system makes it possible to get polished colorful concrete or terrazzo topping budget-friendly and super-fast. Revolutionary Optimal Slab™ Deco is an ’All in One’ solution. It includes all systems, chemicals, and products needed to design concrete floor topping and daily maintenance. This unique floor is made for you only by Certified Concria™

Contractors with the assistance of Concria™ Team Professionals.

CONCRIA OPTIMAL SLAB™ DECO SYSTEM INCLUDES

Deco, concrete topping system

Fast, Power Trowel polishing system

Trowel Hard, finishing aid and hardener

Shield, superhydrophobic sealer

REVOLUTIONARY NANO-SIZED TECHNOLOGY

Concria™ Trowel Hard makes topping cement hydration more efficient. Well hydrated, dense cement paste slows moisture loss during finishing and permanently improves the topping performance. Because of nano silica technology, the risk for delamination, curling and cracking and other drying-related pathologies are significantly reduced. Trowel Hard improves the surface consolidation, and the densifying reaction increases the surface compressive strength and durability, creating an extremely abrasion-resistant. Topping is treated with nano silica during the casting and doesn’t need any silicate (Lithium, Sodium, Potassium) treatment later.

Main benefits

Super-fast application

Polishable in 7 day

Minimum risk of efflorescence, delamination, curling and crazing

2 x more durable than 5000 psi polished concrete

3 x more durable than terrazzo tiles

Green solution (Low VOC)

INCREASING CONCRETE SURFACE LRV

Light Reflective Value is a universal scale that measures the amount of visible and usable light reflected from a surface when illuminated by a light source. It is used in architecture and interior design to determine how much light a color reflects or absorbs. LRV is measured on a scale of 0% being completely absorbing black that reflects no light, to 100% being completely reflecting white that reflects all light. Because the reflectance value is a proportion of the light reflected off the surface, rather than the amount of light that falls on it, typically the brightest whites have an LRV of 85% points, and the darkest blacks have an LRV of 5% points. Increasing concrete surface LRV (light reflective value) will reduce the amount of light needed to achieve the desired illumination per the task at hand.

INCREASE CONCRETE SURFACE LRV AT YOUR FACILITY AND YOU WILL SEE:

Lower amount of human errors

Better quality control

Increased employee satisfaction

Improved safety

Workplace productivity

Energy savings

INCREASING CONCRETE SURFACE LRV

Light Reflective Value is a universal scale that measures the amount of visible and usable light reflected from a surface when illuminated by a light source. It is used in architecture and interior design to determine how much light a color reflects or absorbs. LRV is measured on a scale of 0% being completely absorbing black that reflects no light, to 100% being completely reflecting white that reflects all light.

Because the reflectance value is a proportion of the light reflected off the surface, rather than the amount of light that falls on it, typically the brightest whites have an LRV of 85% points, and the darkest blacks have an LRV of 5% points. Increasing concrete surface LRV (light reflective value) will reduce the amount of light needed to achieve the desired illumination per the task at hand.

INCREASE CONCRETE SURFACE LRV AT YOUR FACILITY AND YOU WILL SEE:

Lower amount of human errors

Better quality control

Increased employee satisfaction

Improved safety

Workplace productivity

Energy savings

LIGHT REFLECTIVE VALUES FOR DIFFERENT CONCRETE SURFACE FINISHES:

Concria™ Optimal Slab white 75%

Concria™ Optimal Slab Light grey 44%

Polished concrete 24%r

Concrete (OPC) 19%

Burn finished concrete 11%,

LIGHT REFLECTIVE VALUES FOR DIFFERENT CONCRETE SURFACE FINISHES:

Concria™ Optimal Slab white 75%

Concria™ Optimal Slab Light grey 44%

Polished concrete 24%

Concrete (OPC) 19%

Burn finished concrete 11%

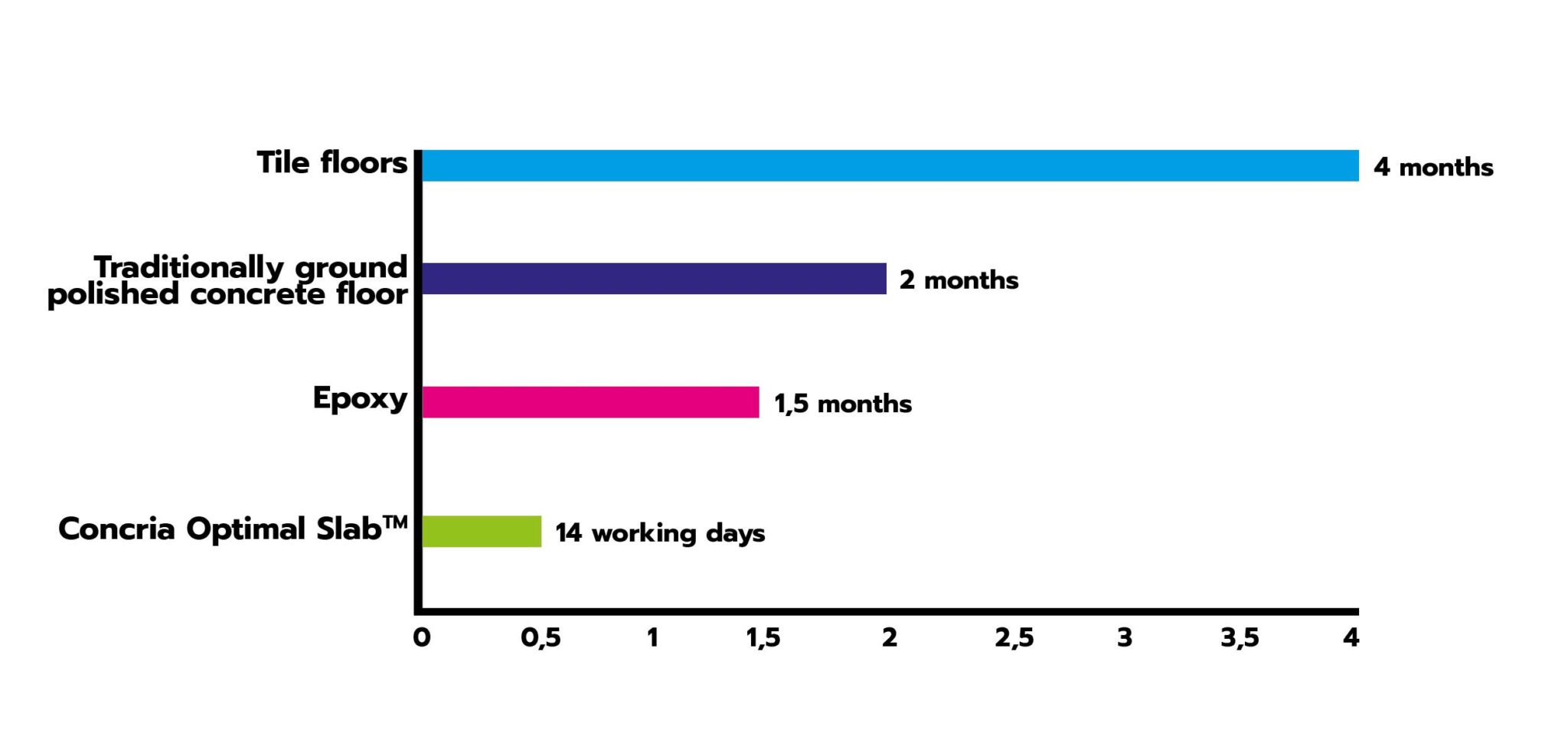

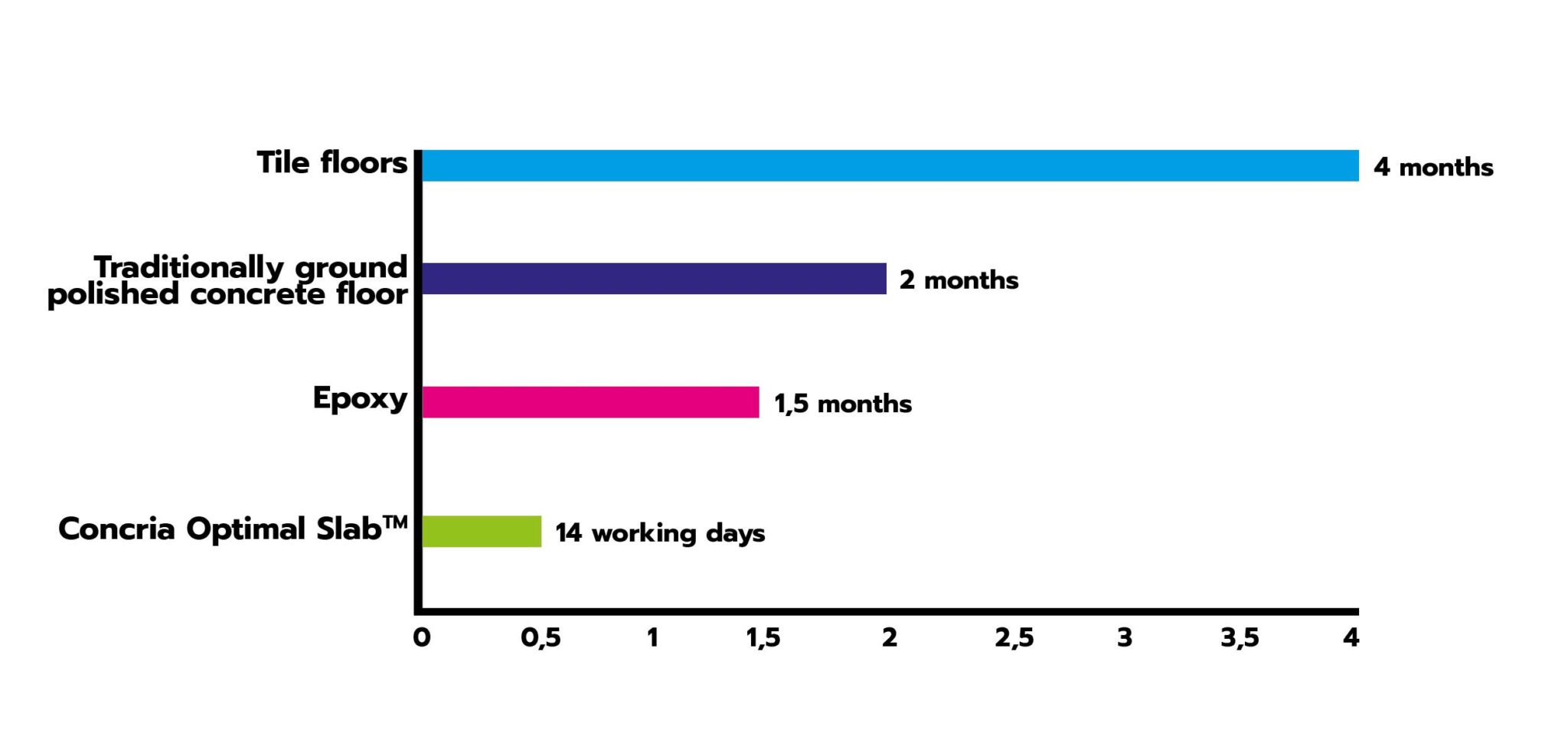

Speed up construction schedules!

Project size 100,000 sqft, four workers

Typically concrete floor can be polished 28 days after casting. Optimal Slab™ surface can be ground and polished into high gloss in just seven days after casting as compression strength is already over 5000 psi. With Concria™ Fast power trowel polishing system, it’s possible to grind and polish the surface 80 % faster than traditional grinding methods.

Speed up construction schedules!

Project size 100,000 sqft, four workers

Typically concrete floor can be polished 28 days after casting. Optimal Slab™ surface can be ground and polished into high gloss in just seven days after casting as compression strength is already over 5000 psi. With Concria™ Fast power trowel polishing system, it’s possible to grind and polish the surface 80 % faster than traditional grinding methods.

BCA - Abrasion Resistance Test

Abrasion resistance is an important performance requirement in commercial and industrial floors. Floors can be exposed to quite aggressive actions from trucks and foot traffic. Tests are carried out using equipment which conforms to the requirements of BS EN 13892-4:2002. Known as the BCA abrasion test machine, the floor surface is assessed by measuring the depth of wear created by three hardened wheels rotating over a circular area for a standard number of revolutions (2850 + / – 10). The depth of wear is used to assess the quality of the floor and classifies it in accordance with BS 8204-2:2003+A2:2011.

4000 psi concrete surface wear of depth after BCA test 0,42 mm

Optimal Slab™ surface wear of depth after BCA test 0,02 mm

BCA - Abrasion Resistance Test

Abrasion resistance is an important performance requirement in commercial and industrial floors. Floors can be exposed to quite aggressive actions from trucks and foot traffic. Tests are carried out using equipment which conforms to the requirements of BS EN 13892-4:2002. Known as the BCA abrasion test machine, the floor surface is assessed by measuring the depth of wear created by three hardened wheels rotating over a circular area for a standard number of revolutions (2850 + / – 10). The depth of wear is used to assess the quality of the floor and classifies it in accordance with BS 8204-2:2003+A2:2011.

4000 psi concrete surface wear of depth after BCA test 0,42 mm

Optimal Slab™ surface wear of depth after BCA test 0,02 mm

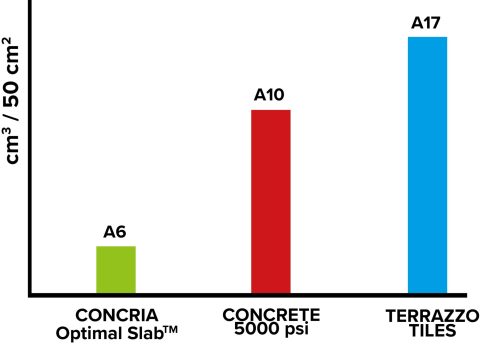

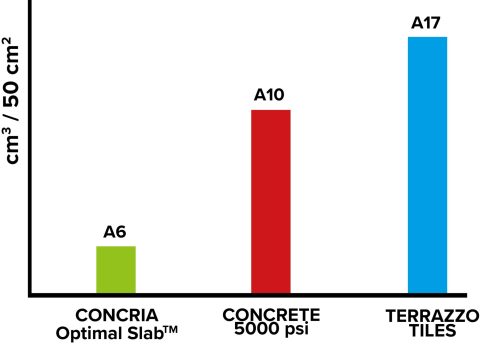

Abrasion resistance, Böhme (DIN EN 13813)

Böhme test

Abrasion resistance is an important performance requirement in commercial and industrial floors. Floors can be exposed to quite aggressive actions from trucks and foot traffic. The disc abrader conforming to Böhme method consists of a rotating wheel made of cast iron, 750 mm dia., with a defined test track to receive the abrasive material (white corundum sand) and a no-vibration specimen holder with a two arms lever loading device.

The test specimen is clamped with an holder and submitted to a test force of 294 +/-3 N. After the abrasive is strew on the disc, the disc starts to rotate with a constant speed for a certain number of cycles according to Standards EN 1338. At the end of the test the abrasion effect is measured as the loss (A= cm3 / 50 cm2) in specimen thickness or volume.

Abrasion resistance, Böhme (DIN EN 13813)

Böhme test

Abrasion resistance is an important performance requirement in commercial and industrial floors. Floors can be exposed to quite aggressive actions from trucks and foot traffic. The disc abrader conforming to Böhme method consists of a rotating wheel made of cast iron, 750 mm dia., with a defined test track to receive the abrasive material (white corundum sand) and a no-vibration specimen holder with a two arms lever loading device.

The test specimen is clamped with an holder and submitted to a test force of 294 +/-3 N. After the abrasive is strew on the disc, the disc starts to rotate with a constant speed for a certain number of cycles according to Standards EN 1338. At the end of the test the abrasion effect is measured as the loss (A= cm3 / 50 cm2) in specimen thickness or volume.