How to mechanically grind and polish SFRC without exposing fibers?

A major concern with SFRC

Jointless steel fiber reinforced (SFRC) concrete flooring is a great floor solution and is becoming more and more popular worldwide. A major concern with SFRC is exposed fibers or loose fibers at the wearing surface. The only way you can grind and polish with ZERO fiber exposure is to apply 2 layers of dry shake hardeners and using minimum 6 kg/m2 (1,2lb/sqft) of this dry shake hardener. Applying more layers than just one or applying a thicker layer has always been a risk. This article will provide a solution to this problem.

Steel fiber concrete flooring can provide superior resistance to minimize cracks in hardened concrete, as well as maximum resistance to withstand heavy loads. SFRC can be made totally without joints. Jointless floors are floors that have no saw cut joints at all, providing spaces without joints as large as 40- or 50-meter-wide span.

SFRC completely eliminates steel fabric reinforcement, saving on both materials and labor

The elimination of conventional reinforcement, and in many cases the reduction of sectional thickness can contribute to some significant productivity improvements. Steel fibers can deliver significant cost savings by reducing material volume, and together with more rapid construction, reduces labor costs. A major concern with SFRC in industrial or commercial project is exposed fibers or loose fibers at the wear surface.

Plain concrete (SFRC)

SFRC floors can be made entirely without any topping, but there is always a high risk that some fibers will exist on top of the surface after final finishing. Premature troweling has been proven to exhibit more fiber at the surface since the cement paste layer can be moved to expose the fibers. Correct timing with a power trowel will produce a smooth, even finish with minimal fiber exposure. SFRC floors still cannot be used for polished concrete projects without a topping, as grinding will always expose fibers.

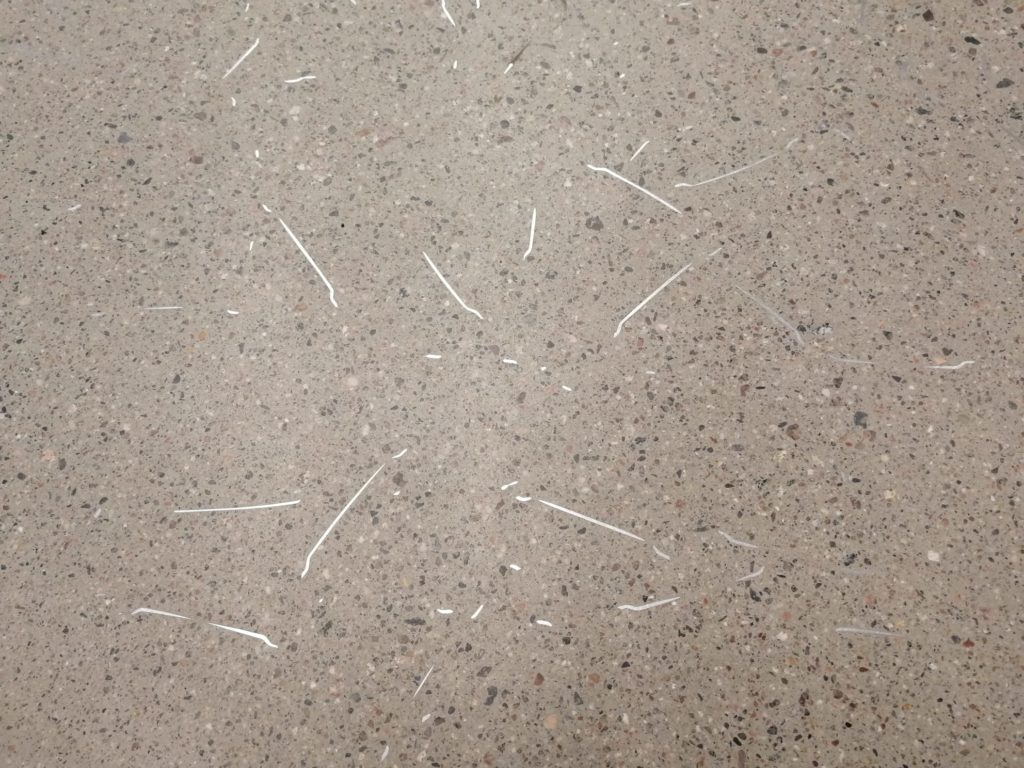

SFRC concrete with 3kg/m2 of dry shake hardener after polishing

Problems with dry shake hardeners

The most common way is to use dry shake hardeners on the top to suppress the steel fibers near the surface. In most cases when dry shake hardeners are used; some fibers still exist on top after finishing, and the problem gets even worse if you mechanically grind and polish the surface; as you will remove the cement paste which hides the fibers. Typically, just 3-4 kg/m2 (0,6-0,8 lb/sqft) of dry shake hardener is applied on top and that is not enough if the surface is going to be polished, as part of the dry shake will get mixed up with base concrete, resulting in just ~1mm layer on top. In many cases grinding and polishing dry shake with only 3-4kg /m2 (0,6-0,8 lb/sqft), you will grind through the dry shake, or you will exposed the fiber which is in the dry shake layer.

The only way you can grind and polish with ZERO fiber exposure is to apply dry shake hardeners in 2-4 layers and using minimum 6 kg/m2 (1,2 lb/sqft) of dry shake hardener or even 10-12 kg/m2 (2-2,5 lb/sqft) with lighter colors. Applying more layers than just one or applying a thicker layer has always been a risk, as dry shake hardeners need water from base concrete to hydrate and for bonding. Thicker or more layers will have a much higher water demand; many contractors avoid applying dry shakes because of a high risk of delamination.

Solution

Patent pending Concria Optimal Slab™ process enables contractors to apply enough dry shake hardener, 6-12kg (1,2-2,4 lb/sqft per m2 of Dry Shake hardeners in 2-4 layers which can be easily bonded together with Concria™ Trowel Hard (Nano silica liquid) product.

Concria™ Trowel Hard is sprayed between the dry shake hardener layers. It delivers virtually pure silica in nanoparticles small enough to penetrate dry shake pore structure and glue all the layers together. In the pores, it reacts and creates new calcium silicate hydrate (CSH) that bonds to the existing CSH. It also bonds directly to other silica, including itself. When applied to a dry shake hardened surface, it reacts, bonds and then uses bonded silica as a platform for additional bonding. In independent laboratory tests, it has been shown that even using 12 kg/m2 of dry shake in 4 layers, the dry shake hydration rate is almost 90 % whereas without Nano silica, the hydration rate is only 68 %.

In just five minutes and our Concria™ FAST system will transform your power trowel into a diamond grinding and polishing machine.

SFRC with dry shake hardener can be polished faster and more easily with Concria™ Fast power trowel polishing systems

Concria™ Fast power trowel polishing system has been used successfully in tens of millions sqft of polished dry shakes hardeners floors in more than 40 countries. Power trowel polishing has an average labor reduction of 80 % compared to traditional planetary grinding. Contractors with power trowel capabilities can attract bigger jobs than ever before as well as satisfy customers who want great-looking floors.

Concria™ Fast is the fastest and best solution for grinding and polishing new dry shake hardened floors in commercial or industrial facilities, where a long-lasting, high-quality finish is required.

If you would like more information, please get in touch with our sales team at: [email protected]

Mika Ahonen

CTO and Founder of Concria