NEW GENERATION DRY-SHAKE HARDENER FLOOR

Better bonding. More uniform color. Minimized shrinkage. No Delamination.

Since the 1980s, dry-shake hardener has been standard industrial concrete flooring surface due to its low installation and maintenance costs and primarily because of high durability. The dry-shake hardener floors can fail, resulting in extensive repair costs. Typical problems are surface delamination, plastic shrinkage, and ununiform color. We wanted to take up the challenge and develop a method that enables contractors to make better dry-shake hardener surfaces even under challenging conditions like high heat, wind, sun, or low humidity. Concria™ Optimal Slab™ Industrial topping is ‘a new generation’ dry-shake hardener solution developed and patented in Finland.

Better bonding. More uniform color. Minimized shrinkage.

No Delamination.

Since the 1980s, dry-shake hardener has been standard industrial concrete flooring

surface due to its low installation and maintenance costs and primarily because of high durability. The dry-shake hardener floors can fail, resulting in extensive repair costs.

Typical problems are surface delamination, plastic shrinkage, and ununiform color. We

wanted to take up the challenge and develop a method that enables contractors to make

better dry-shake hardener surfaces even under challenging conditions like high heat, wind, sun, or low humidity. Concria™ Optimal Slab™ Industrial topping is ‘a new generation’ dry-shake hardener solution developed and patented in Finland.

WHAT IS CONCRIA OPTIMAL SLAB™ INDUSTRIAL?

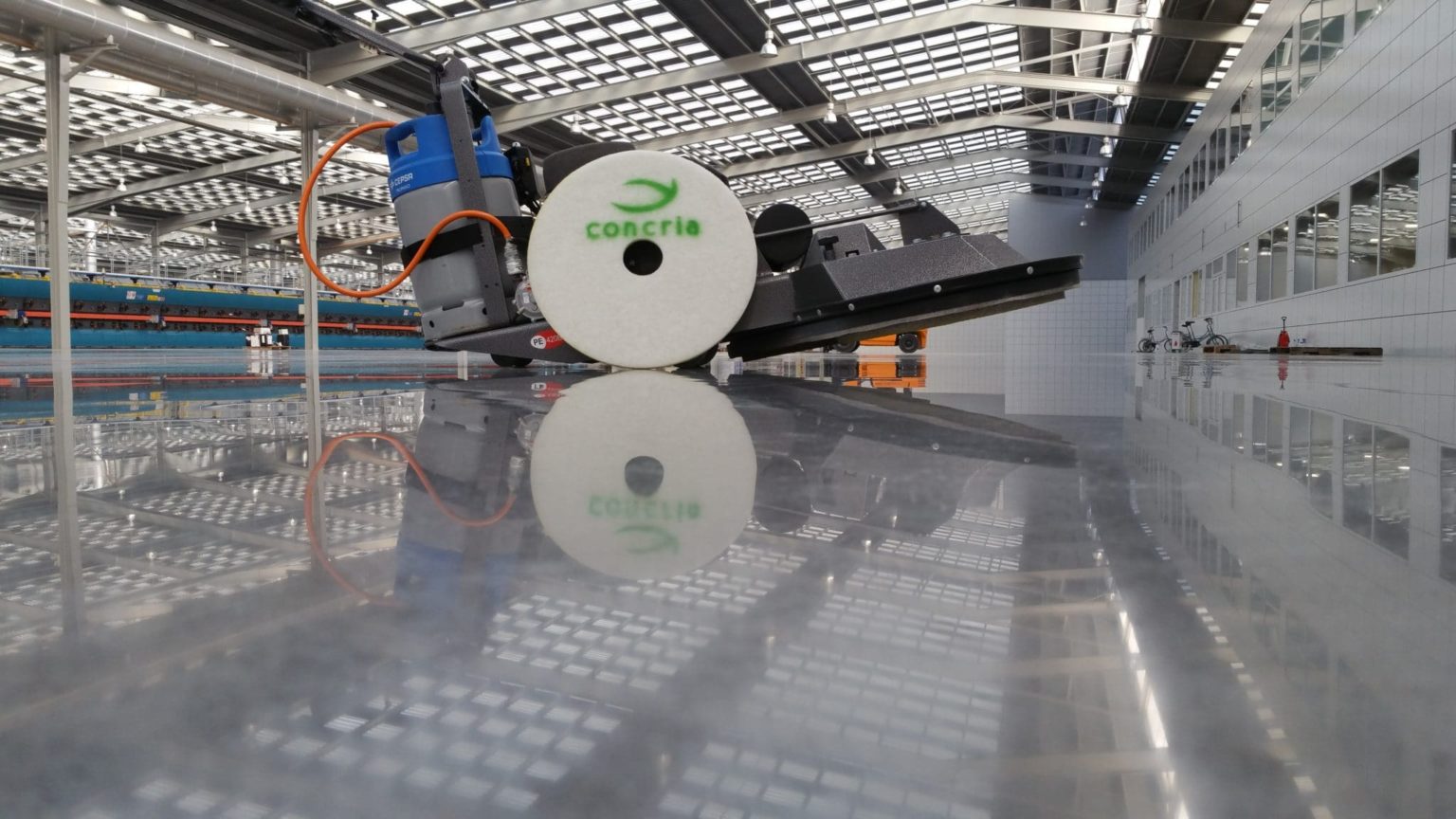

It is a method that includes all the products needed to make a better dry-shake hardener floor. The secret of a durable, long-lasting, and the almost maintenance-free floor is a combination of industrial dry-shake, nanotechnology, and the unique products Concria has developed for surface finishing.

Concria Optimal Slab™ Industrial dry-shakes is made from uniquely hard and coarse aggregates, modified Portland cement, polypropylene microfibers, and additives. The cement reacts with Concria™ Trowel Hard nanosilica, which is applied during the installation, improves the bonding, and makes the surface denser and harder. Thanks to the polypropylene fibers and Concria’s installation method, plastic shrinkage and delamination are minimized, and the finished surface is smoother and glossier than usual. The smooth and denser surface reduces forklift tire wear and is easier to maintain.

Concria Optimal Slab ™ Industrial product range

Industrial Dry-Shake hardener

Trowel Hard- Nano Silica finishing aid

Sleek – Diamond maintenance disc’s

WHAT IS CONCRIA OPTIMAL SLAB™ INDUSTRIAL?

It is a method that includes all the products needed to make a better dry-shake hardener floor. The secret of a durable, long-lasting, and the almost maintenance-free floor is a combination of industrial dry-shake, nanotechnology, and the unique products Concria has developed for surface finishing.

Concria Optimal Slab™ Industrial dry-shakes is made from uniquely hard and coarse aggregates, modified Portland cement, polypropylene microfibers, and additives.

The cement reacts with Concria™ Trowel Hard nanosilica, which is applied during the installation, improves the bonding, and makes the surface denser and harder.

Thanks to the polypropylene fibers and Concria’s installation method, plastic shrinkage and delamination are minimized, and the finished surface is smoother and glossier than usual. The smooth and denser surface reduces forklift tire wear and is easier to maintain.

Concria Optimal Slab ™ Industrial product range

Industrial Dry-Shake hardener

Trowel Hard- Nano Silica finishing aid

Sleek – Diamond maintenance disc’s

100% DUST-FREE SURFACE

Nanosilica is sprayed into the Concria Optimal Slab™ surface during the installation. Nanosilica is significantly improving the cement hydration and making the surface completely dust-free. The entire floor is finished at once and does not require lithium or sodium treatment later.

ECOLOGICAL CHOICE

Sustainability and being ecological are essential topics in the modern world. According to the University of Linköping in Sweden, concrete floor greenhouse gas emission GWP- factor is 90, significantly lower than Epoxy (GWP 17 000). Concria Optimal Slab™ is a concrete floor that improves indoor air quality by being a dust-free with no toxic chemicals nor high chromate substances.

Concria Optimal Slab™ Industrial flooring is used in

Industrial and parking garages

Logistics and data centers

Waste management facilities

Terminals

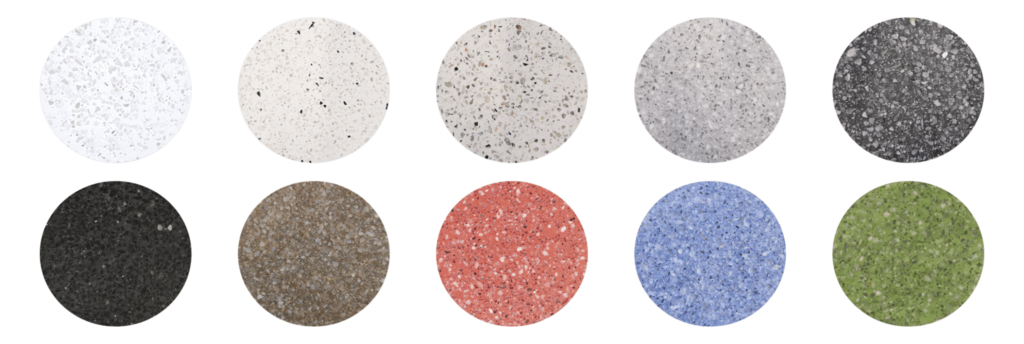

CREATE BRIGHTER, LIGHTER, HEALTHIER AND MORE PRODUCTIVE SPACE

Light reflectivity impacts directly to functionality, productivity, cousines, safety and energy consumptionv of a space. Light reflectance value (LRV) tells how much the surface reflects daylight and artificial light. All white surface has the value 100% and all black matt surface gets 0%. Floors with high LRV values helps reflect the light all around the space. Energy consumtion can be effected by the colour scheme of the interior

White surfaces are not done only with epoxy anymore, now you can have the same esthetic look with maintenance free, high durability dry-shake.

LIGHT REFLECTIVE VALUES FOR DIFFERENT CONCRETE SURFACE FINISHES:

Concria Optimal Slab White 75%

Concria Optimal Slab Light gray 44%

Polished concrete surface 24%

Concrete (OPC) 19%

Burn finished concrete 11%

HIDE METAL FIBERS

The benefits of using dry-shake toppings in concrete floors have been known for a while. In Slab-on-grade floors, where typically steel and plastic macrofibres are used, visible fibers on the top are a problem. Plastic fibers can be burned away but removing steel fibers is a challenge. Patented Concria Optimal Slab™ Industrial floors hide all metal and plastic fibers, as you can easily apply 7 kg of dry-shake per m2 with Concria™ Trowel Hard nanosilica.

benefits

Fast implementation and deployment

Dense, smooth, and seamless surface

Maintains good indoor air quality

Very low maintenance and service costs

HIDE METAL FIBERS

The benefits of using dry-shake toppings in concrete floors have been known for a while. In Slab-on-grade floors, where typically steel and plastic macrofibres are used, visible fibers on the top are a problem. Plastic fibers can be burned away but removing steel fibers is a challenge. Patented Concria Optimal Slab™ Industrial floors hide all metal and plastic fibers, as you can easily apply 7 kg of dry-shake per m2 with Concria™ Trowel Hard nanosilica.

benefits

Fast implementation and deployment

Dense, smooth, and seamless surface

Maintains good indoor air quality

Very low maintenance and service costs

100% DUST-FREE SURFACE

Nanosilica is sprayed into the Concria Optimal Slab™ surface during the installation. Nanosilica is significantly improving the cement hydration and making the surface completely dust-free. The entire floor is finished at once and does not require lithium or sodium treatment later.

ECOLOGICAL CHOICE

Sustainability and being ecological are essential topics in the modern world. According to the University of Linköping in Sweden, concrete floor greenhouse gas emission GWP- factor is 90, significantly lower than Epoxy (GWP 17 000). Concria Optimal Slab™ is a concrete floor that improves indoor air quality by being a dust-free with no toxic chemicals nor high chromate substances.

Concria Optimal Slab™ Industrial flooring is used in

Industrial and parking garages

Logistics and data centers

Waste management facilities

Terminals

CREATE BRIGHTER, LIGHTER, HEALTHIER AND MORE PRODUCTIVE SPACE

Light reflectivity impacts directly to functionality, productivity, cousines, safety and energy consumptionv of a space. Light reflectance value (LRV) tells how much the surface reflects daylight and artificial light. All white surface has the value 100% and all black matt surface gets 0%. Floors with high LRV values helps reflect the light all around the space. Energy consumtion can be effected by the colour scheme of the interior

White surfaces are not done only with epoxy anymore, now you can have the same esthetic look with maintenance free, high durability dry-shake.

LIGHT REFLECTIVE VALUES FOR DIFFERENT CONCRETE SURFACE FINISHES:

Concria Optimal Slab White 75%

Concria Optimal Slab Light gray 44%

Polished concrete surface 24%

Concrete (OPC) 19%

Burn finished concrete 11%

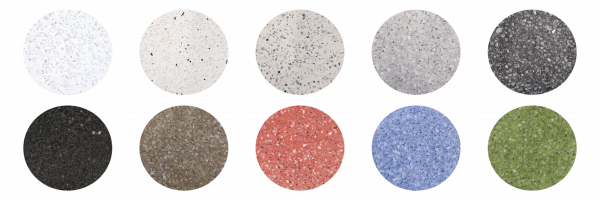

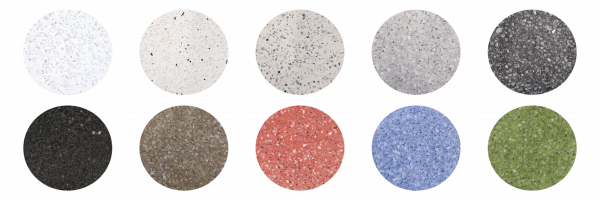

Surface finishing and color options

Burn finishing with a power trowel is typically enough for industrial floors. The floor becomes smooth and easy to keep clean. If you want the best possible surface, you should also grind and polish it with the Concria™ Fast power trowel polishing system to a high shine. Concria Optimal Slab™ Industrial has one primary color; Concrete Gray. Our dry shakes are also available in all RAL colors.

Surface finishing and color options

Burn finishing with a power trowel is typically enough for industrial floors. The floor becomes smooth and easy to keep clean. If you want the best possible surface, you should also grind and polish it with the Concria™ Fast power trowel polishing system to a high shine. Concria Optimal Slab™ Industrial has one primary color; Concrete Gray. Our dry shakes are also available in all RAL colors.

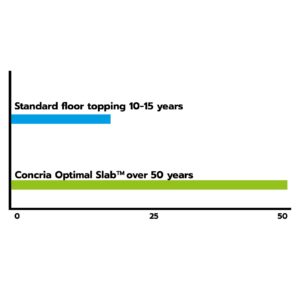

LOW MAINTENANCE COSTS AND LONG LIFE

Concria Optimal Slab™ Industrial dry-shake floor beats conventional floor toppings such as epoxy in cost-effectiveness, maintenance-free and longevity. The screed is completed by a single contractor in connection with the floor casting, and no separate installation process is required. You must renew the standard floor topping approximately 10 to 15 years when the corresponding service life on dry-shake floors is more than 50 years. If the Optimal Slab™ floor needs maintenance, it is enough to polish it without closing the premises.

CONCRIA OPTIMAL SLAB FLOOR™ HAS A VERY FAST ROI

Pricing of Concria Optimal Slab™ is competitive with traditional dry-shake flooring, but the benefits are far greater:

The risk of plastic shrinkage is significantly reduced

Better adhesion to the base concrete

More uniform color and completely dust-free surface

A smoother and denser surface makes it easier to clean

Longer service life and almost maintenance-free

Reliable even in difficult casting conditions

LOW MAINTENANCE COSTS AND LONG LIFE

Concria Optimal Slab™ Industrial dry-shake floor beats conventional floor toppings such as epoxy in cost-effectiveness, maintenance-free and longevity. The screed is completed by a single contractor in connection with the floor casting, and no separate installation process is required. You must renew the standard floor topping approximately 10 to 15 years when the corresponding service life on dry-shake floors is more than 50 years. If the Optimal Slab™ floor needs maintenance, it is enough to polish it without closing the premises.

CONCRIA OPTIMAL SLAB FLOOR™ HAS A VERY FAST ROI

Pricing of Concria Optimal Slab™ is competitive with traditional dry-shake flooring, but the benefits are far greater:

The risk of plastic shrinkage is significantly reduced

Better adhesion to the base concrete

More uniform color and completely dust-free surface

A smoother and denser surface makes it easier to clean

Longer service life and almost maintenance-free

Reliable even in difficult casting conditions