NO SCRATCHES, NO BURN MARKS, BETTER SHINE!

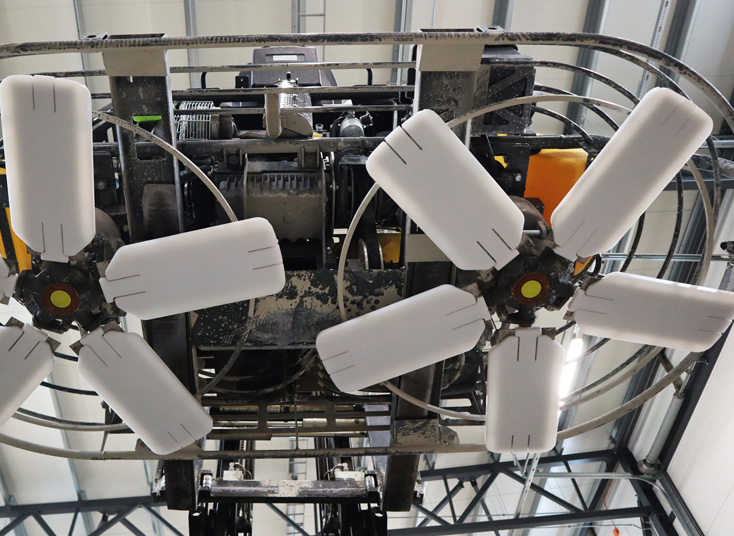

Time plays a significant role in the concrete finishing. It takes 30-60 minutes to change standard blades, but Slide Blades can be changed in just few seconds.

Longevity, quick to chance and better price per square foot equalizes to the Slide Blades becoming an everyday finishing blade. Slide Blades consumption is over 200,000 sq ft when used after combination/Finishing blades.

NO SCRATCHES, NO BURN MARKS, BETTER SHINE!

Time plays a significant role in the concrete finishing. It takes 30-60 minutes to change standard blades, but Slide Blades can be changed in just few seconds.

Longevity, quick to chance and better price per square foot equalizes to the Slide Blades becoming an everyday finishing blade. Slide Blades consumption is over 200,000 sq ft when used after combination/Finishing blades.

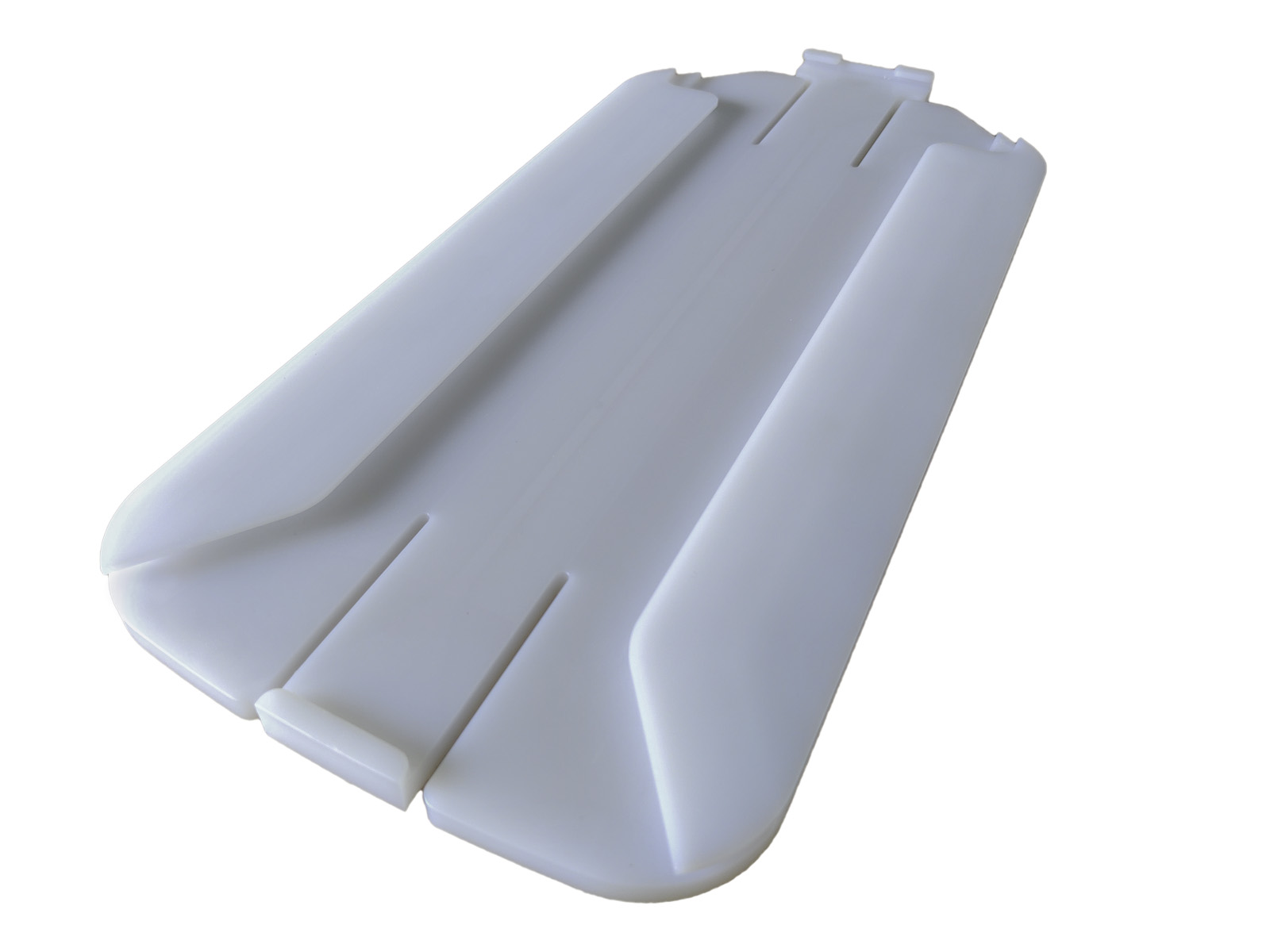

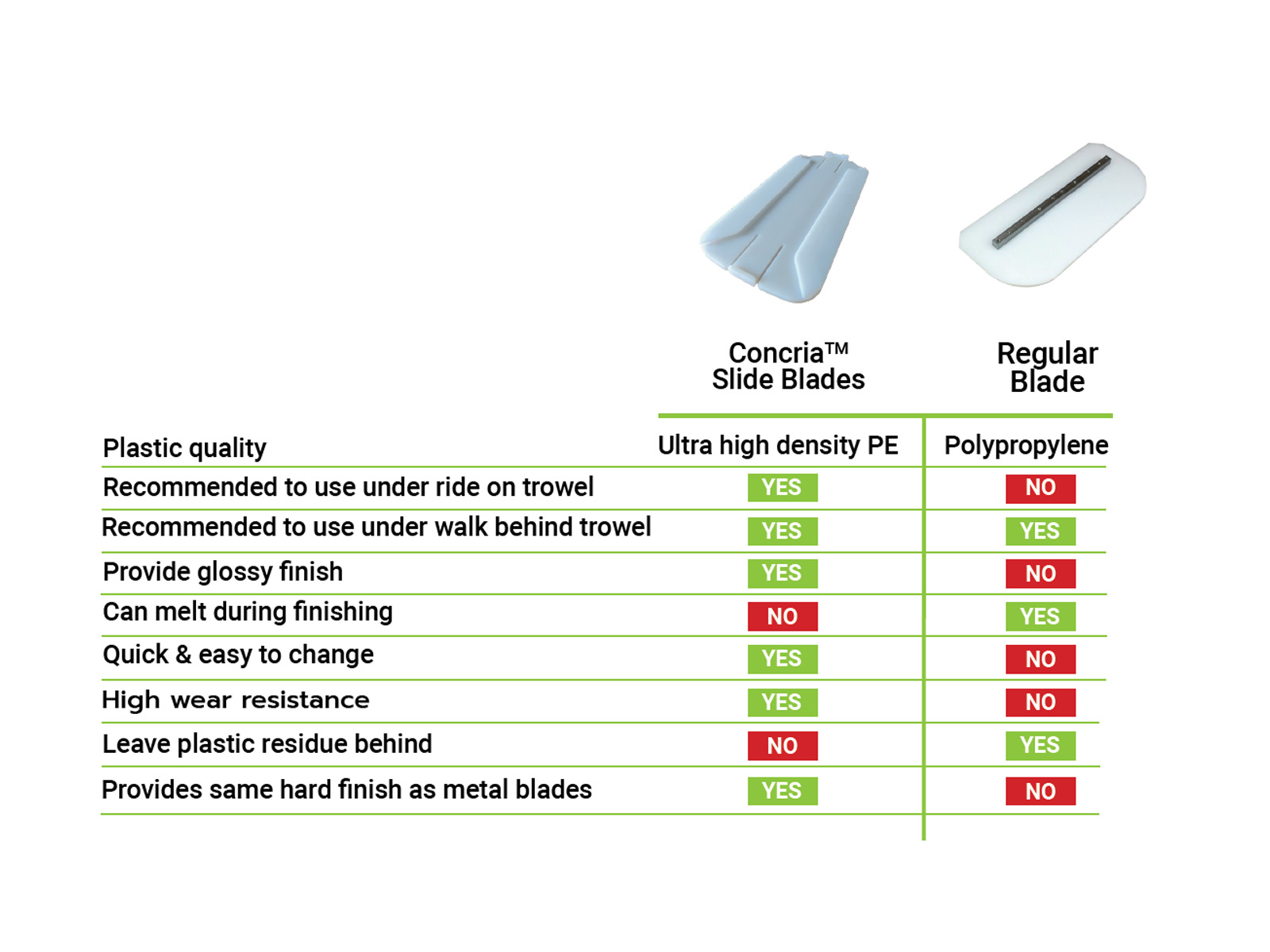

Revolutionary, patented Concria™ Plastic Slide Blades

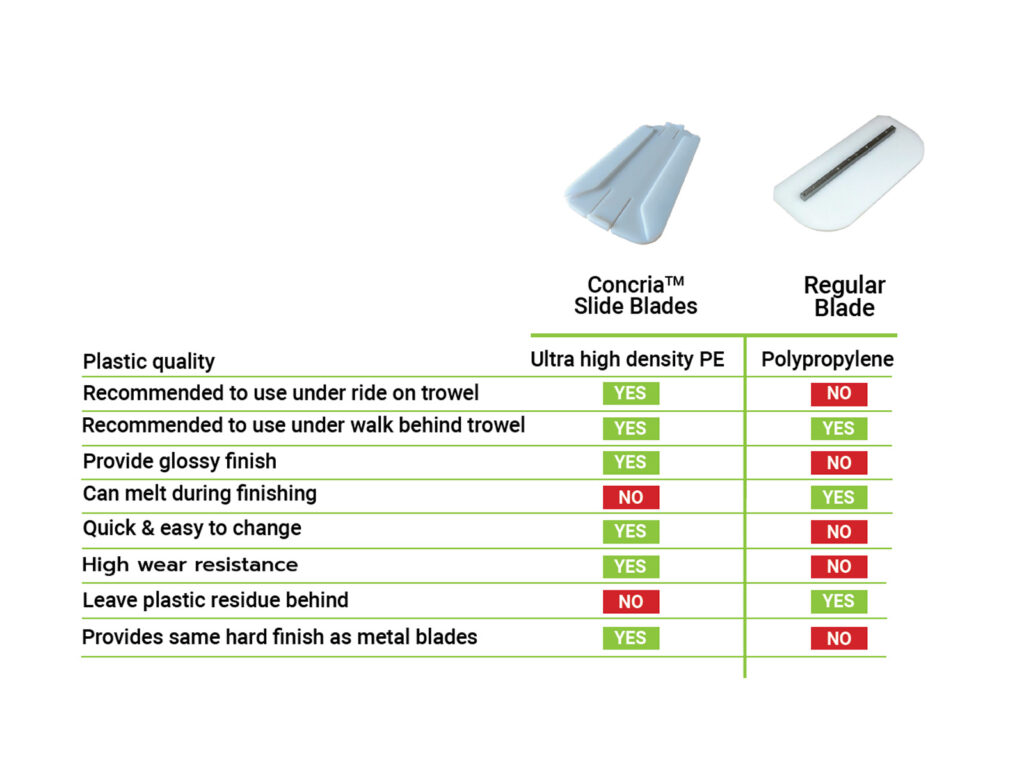

Plastic or teflon blades have specified for long time for all decorative concrete projects such as stain, dye, shake on, integral pigments, polished etc. Burnished steel trowel finish increases the potential for mottling and difficulty in uniformly polishing the slab. Slide Blades totally eliminates the risk of leaving dark burnish marks while power troweling concrete or dry shake hardener floors.

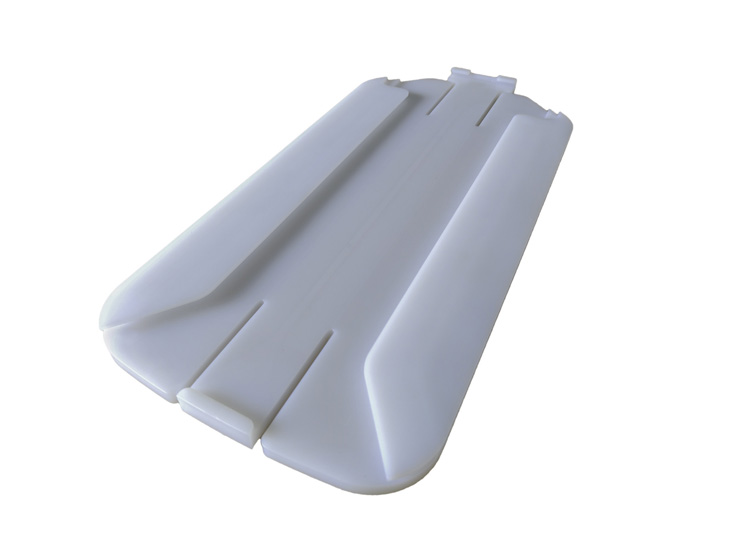

Patented Slide Blades can be easily slided on the standard 6” metal finishing blades in just seconds without any screwing.

Revolutionary, patented Concria™ Plastic Slide Blades

Plastic or teflon blades have specified for long time for all decorative concrete projects such as stain, dye, shake on, integral pigments, polished etc. Burnished steel trowel finish increases the potential for mottling and difficulty in uniformly polishing the slab. Slide Blades totally eliminates the risk of leaving dark burnish marks while power troweling concrete or dry shake hardener floors.

Patented Slide Blades can be easily slided on the standard 6” metal finishing blades in just seconds without any screwing.

High wear resistance

Slide Blades are made of hardest quality plastic and provide outstanding wear resistance, very low coefficient of friction, and exceptional temperature and impact properties. Slide Blades provides as hard and glossy finish than standard metal finishing blades.

size:

10”/ 250 mm for 24” walk behind

14”/ 300 mm for 36” ride on

18″/ 400 mm for 48″ ride on

High wear resistance

Slide Blades are made of hardest quality plastic and provide outstanding wear resistance, very low coefficient of friction, and exceptional temperature and impact properties. Slide Blades provides as hard and glossy finish than standard metal finishing blades.

size:

10”/ 250 mm for 24” walk behind

14”/ 300 mm for 36” ride on

18″/ 400 mm for 48″ ride on

Slide Blades are made of the hardest quality plastic and provide:

Outstanding wear resistance

Very low coefficient of friction

Exceptional temperature and impact properties

Slide Blades are made of the hardest quality plastic and provide:

Outstanding wear resistance

Very low coefficient of friction

Exceptional temperature and impact properties